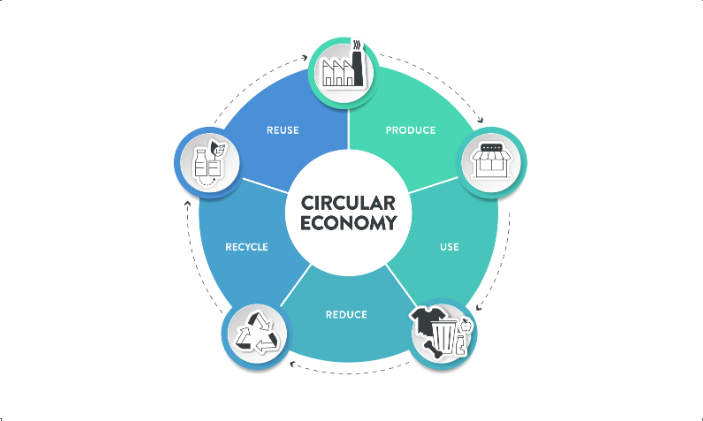

The plastics industry is undergoing a revolution. The circular economy, a model focused on keeping materials in use for longer, is gaining traction. But what about the hidden environmental cost of transporting plastics throughout this loop? Trucks might be the go-to for many manufacturers, but there’s a more sustainable path forward.

Shifting Gears: Rail as the Eco-Friendly Engine

Trains are the unsung heroes of sustainable transportation. They boast superior fuel efficiency compared to trucks, often using up to 75% less fuel per ton of freight [source: Union Pacific]. This translates to a significant reduction in greenhouse gas emissions, a key factor in combating climate change.

For plastics manufacturers, particularly those dealing with large volumes of recycled materials or finished products, utilizing rail networks can significantly reduce their environmental footprint.

Optimizing the Package: Less Space, More Impact

Transportation isn’t just about the vehicle; it’s about the cargo itself. Imagine shipping air instead of product! By optimizing packaging to reduce wasted space, manufacturers can not only decrease transportation costs but also minimize the environmental impact. Here’s how:

- Right-sizing packaging: Ditch the oversized boxes and use containers that perfectly fit the product. This reduces the total volume transported.

- Lightweighting materials: Explore innovative, lightweight packaging materials that offer sufficient protection without adding unnecessary weight.

- Stackable and nestable designs: Design packaging that allows for efficient stacking and nesting, maximizing space utilization during transport.

Closing the Loop: Recycled Content, Recycled Benefits

The circular economy thrives on keeping resources in use. This extends to the transportation materials themselves. Trucks, trailers, and even shipping containers can be manufactured using a significant percentage of recycled content, reducing reliance on virgin materials and creating a truly closed-loop system.

The Road Ahead: A Sustainable Future for Plastics

By embracing these strategies, plastics manufacturers can play a key role in creating a more sustainable transportation network within the circular economy. From choosing eco-friendly transportation methods to optimizing packaging and incorporating recycled content, every step counts.

The future of plastics is circular, and transportation is a vital cog in this green machine. By working together, the industry can ensure a cleaner, more sustainable future for generations to come.